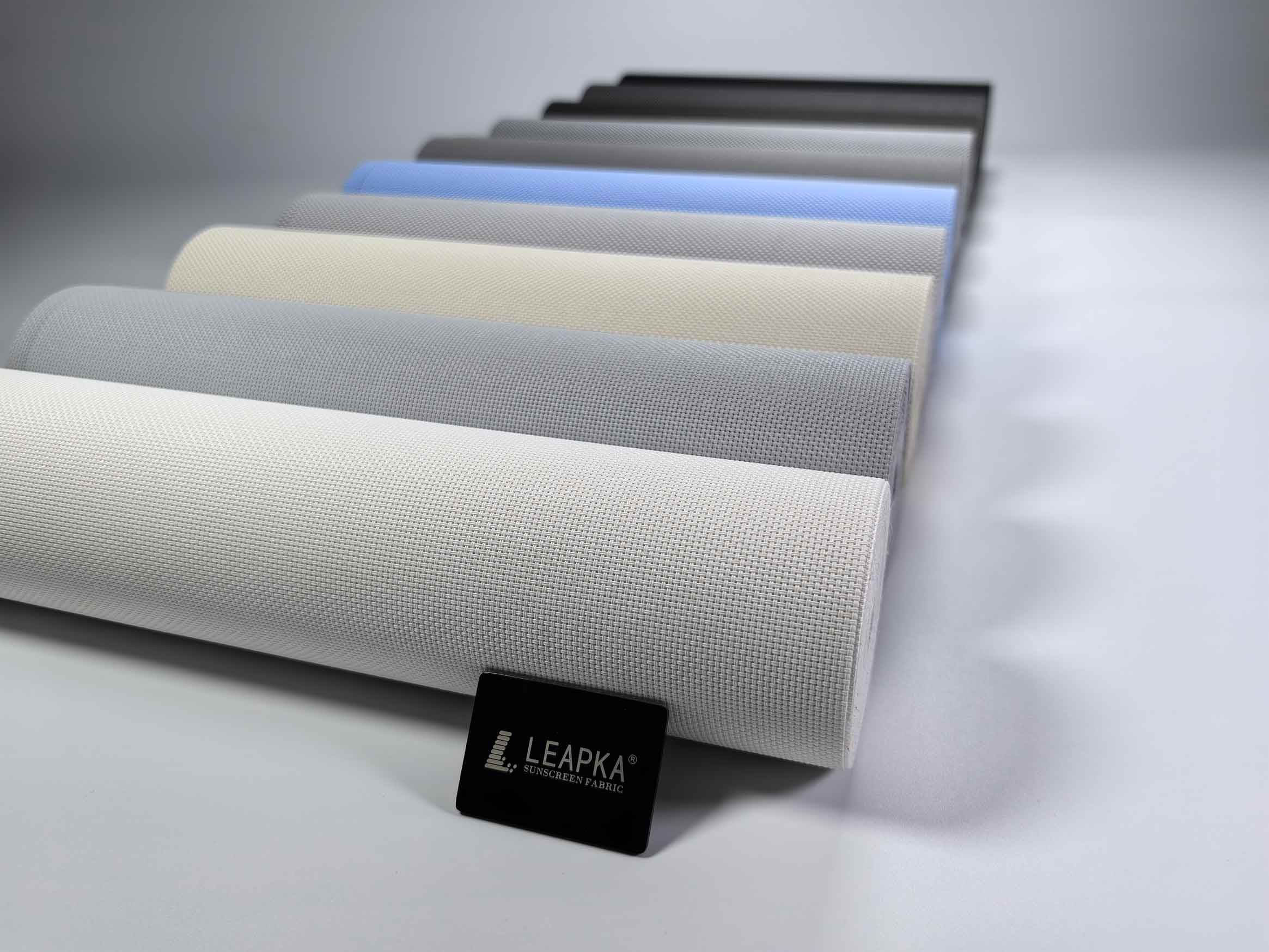

Precision Engineered: A Technical Overview of the LEAPKA L1-512 Black/White Fabr

In the specialized world of architectural textiles, performance is dictated by precise engineering. The LEAPKA L1-512 Black/White stands as a paragon of this principle, a sunscreen fabric meticulously designed within the L1 Thin Plain Weave series to deliver a specific aesthetic and functional outcome. This analysis dissects the technical DNA of this distinctive material, providing the data-driven insights necessary for informed specification.

Deconstructing the Material Profile

The L1-512 is a sophisticated composite, engineered for both visual impact and enduring performance.

Material Architecture: A 30% High-Tenacity Polyester / 70% PVC Coating matrix. This industry-optimized blend leverages the formidable structural integrity and dimensional stability of polyester yarns, which are then encapsulated by a advanced PVC coating. This coating is responsible for the fabric's exceptional resistance to ultraviolet radiation, environmental pollutants, and physical wear, ensuring the striking black-and-white contrast remains vivid over time.

Surface Density: 420 g/m² ± 5%. This specific weight classifies it as a versatile, medium-weight roller blinds fabric. It provides sufficient substance for stability and wind resistance in most commercial and residential applications, while remaining agile enough for smooth operation in a variety of roller mechanisms, including those designed for larger window formats.

Dimensional Specifications: The fabric is available in standard industry widths of 200 cm (78 inches), 250 cm (98 inches), and 300 cm (118 inches), facilitating projects with expansive glazing. It is supplied on 35-meter rolls, a length that optimizes yield for medium to large-scale projects and minimizes material waste during the fabrication process.

Optical Performance & Functional Mechanics

The core purpose of the L1-512 extends beyond shading to intelligent light management.

Openness Factor: 5%. This critical metric is engineered to achieve an optimal balance. It permits a soft, diffused natural light to permeate an interior space, effectively eliminating harsh glare on screens and work surfaces—a primary concern in modern environments. Simultaneously, this level of openness maintains a clear outward visual connection, preventing the enclosed feeling associated with blackout solutions, all while significantly reducing solar heat gain.

Weave Density & Construction: A yarn count of 46 x 44 per inch indicates a tight, fine plain weave. This high density is fundamental to the fabric's durability, aesthetic consistency, and its ability to maintain the precise 5% openness factor. The use of yarns with a 0.32 mm diameter allows for this fine, smooth texture.

Aesthetic Function: The Black/White colorway is not merely decorative. The contrasting colors can influence the perceived openness and light diffusion characteristics from different angles and lighting conditions, adding a dynamic visual element to its functional role.

Fabrication Compatibility & Finishing

Designed for seamless integration into manufacturing workflows, the L1-512 supports a range of professional finishing techniques.

Cutting: It is fully compatible with cold knife, ultrasonic, and crush cutting methodologies. Ultrasonic cutting is highly recommended to achieve thermally sealed, fray-free edges that signify a premium-quality product.

Seaming & Hemming: The fabric performs excellently with thermal, high-frequency (HF), and ultrasonic welding techniques, which are superior for creating nearly invisible and incredibly strong seams for extra-wide applications. It is also compatible with industrial sewing for hem creation, provided UV-stable thread is used.

Durability & Preservation

The integrity of the L1-512 is designed for longevity.

Maintenance Protocol: Routine upkeep involves light dusting with a vacuum's soft brush attachment. For more thorough cleaning, a gentle wipe with a soft cloth dampened with a mild soap solution is effective. Its coated surface resists staining, and the use of abrasive cleaners or harsh solvents is strictly contraindicated to preserve the coating's integrity and color.

Conclusion: The Specification Standard

The LEAPKA L1-512 Black/White is a roller blinds fabric defined by its precise technical orchestration. Every parameter, from its 5% openness and 420 g/m² weight to its fine weave and fabrication-ready design, is a calculated decision aimed at delivering reliable, high-performance solar management with a bold aesthetic signature. For projects demanding both scientific performance and distinctive design, the L1-512 presents a compelling, data-backed proposition.