Fabrication Guidelines: Manufacturing with L3 Series Materials

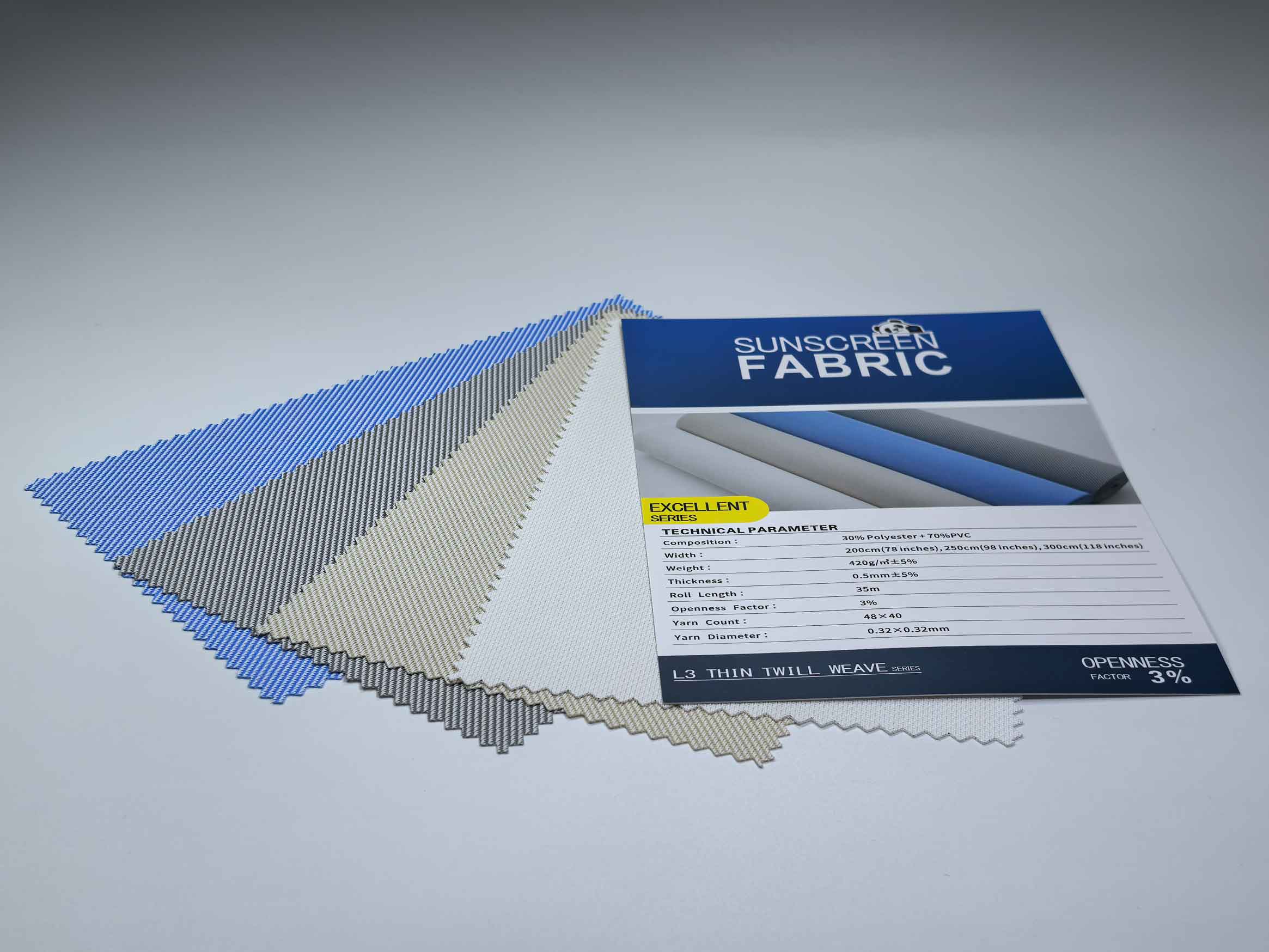

The transformation of the L3 Thin Twill Weave Series into premium window treatments demands meticulous attention to material properties and manufacturing protocols. This refined collection of Sunscreen fabrics presents specific considerations for manufacturers developing customized window covering solutions. This detailed guide addresses practical aspects of working with these advanced materials to ensure superior outcomes in finished products.

Product Applications and System Configurations

The series supports various finished product categories:

Standard Roller Mechanisms: Conventional solutions for typical window applications

Automated Systems: Integration with motorized control and operating mechanisms

Specialized Configurations: Custom solutions for unique architectural demands

Commercial Implementations: Large-scale applications for business environments

Material Handling and Preparation

Proper handling ensures optimal manufacturing results:

Color Coordination: Systematic organization of different color variants to maintain clarity

Storage Protocols: Maintenance of clean, controlled storage conditions to preserve material integrity

Layout Strategy: Strategic material planning to minimize waste and ensure pattern continuity

Cutting Techniques and Precision Methods

Various cutting methodologies require specific considerations:

Precision Cutting: Accurate cutting protocols for clean edges and proper alignment

Pattern Consistency: Careful attention to twill weave pattern continuity and direction

Quality Verification: Regular monitoring of cutting accuracy and edge quality

Color-Specific Manufacturing Considerations

Different variants demand particular attention:

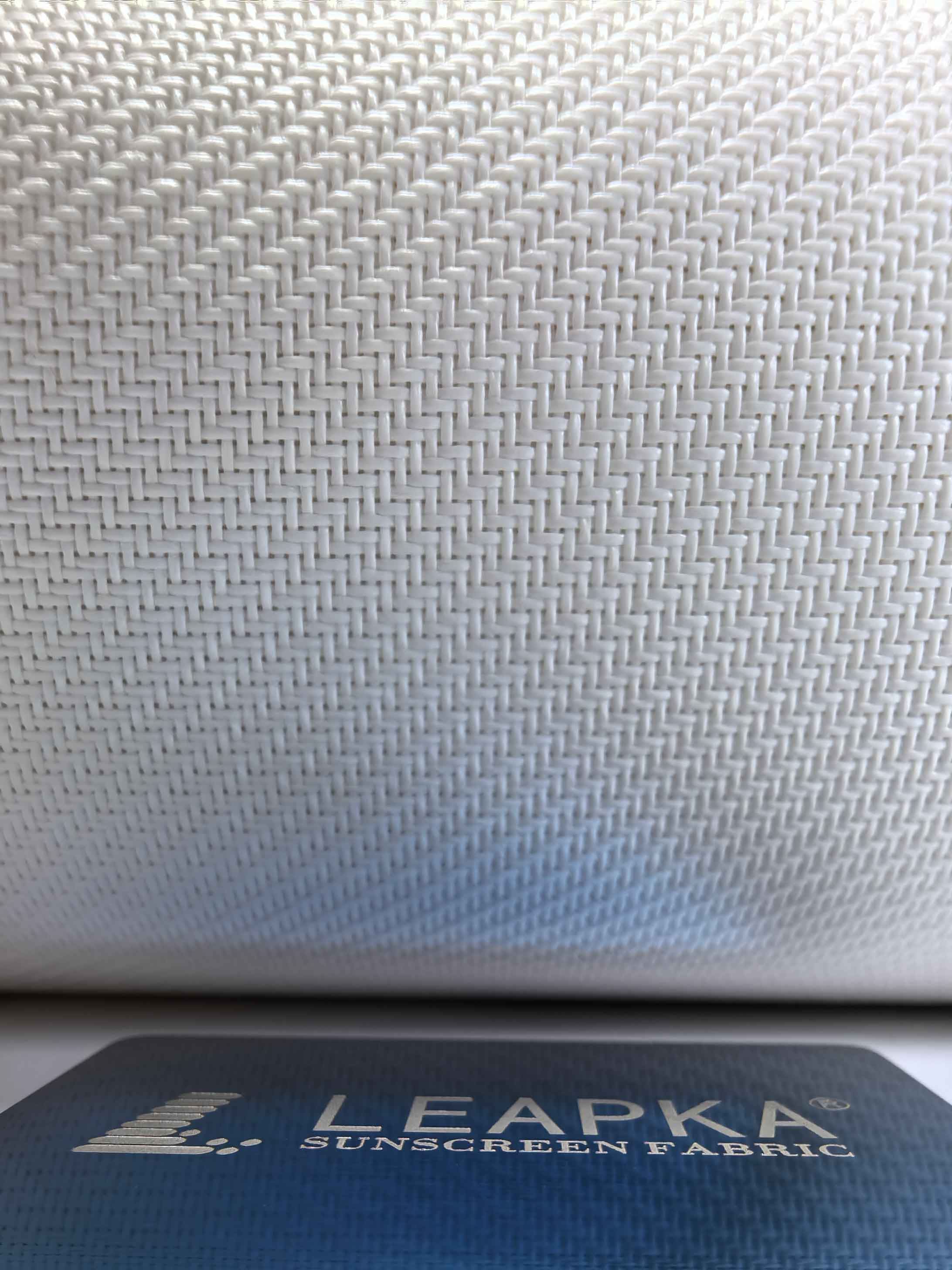

Light Tones (L3-301): Special precautions to prevent surface contamination

Dual-Tone Patterns: Attention to color distribution and pattern alignment

Medium Shades (L3-302): Careful handling to maintain color consistency

Seaming and Joining Procedures

Multiple techniques support professional product assembly:

Thermal Bonding: Heat-based joining methods for durable, clean seams

High-Frequency Welding: Advanced joining technology for robust, discreet seams

Stitching Methods: Conventional sewing techniques with appropriately colored thread selection

The successful fabrication of L3 series-based window treatments requires thorough understanding of material characteristics throughout the production process. By implementing appropriate manufacturing techniques and quality assurance measures, fabricators can create superior products that deliver both aesthetic sophistication and dependable performance as exceptional Roller blinds Fabrics solutions.