Production Protocols: Fabricating with the L1-500 Series

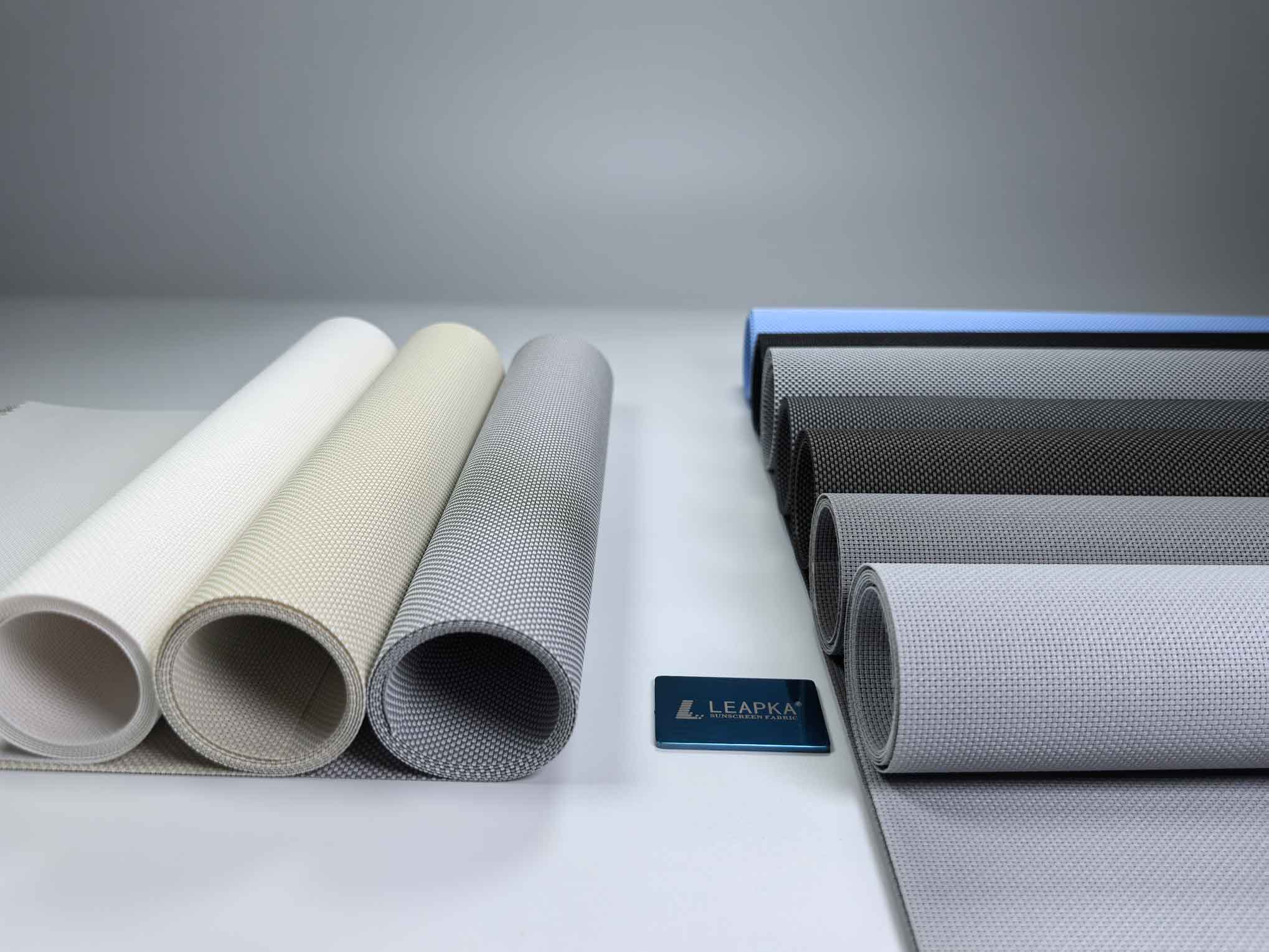

Successfully transforming the L1-500 series from bulk fabric into premium window coverings requires a blend of precision craftsmanship and an understanding of the material's specific characteristics. This guide outlines the primary end-uses and critical, color-aware considerations for manufacturers working with this versatile line of Roller blinds Fabrics.

Defined End-Product Categories

The series is ideally suited for fabrication into several key product types:

Interior Roller Shades/Blinds: The primary application. Its weight and pliability make it perfect for manual or motorized roller systems, including those housed in cassettes for a clean, finished look.

Vertical System Components: The fabric can be precision-cut into vertical vanes or panels for specialized track systems, offering an alternative aesthetic for floor-to-ceiling glass or room dividers.

Custom Architectural Elements: For bespoke projects, the fabric can be implemented in fixed or operable interior screens, light-diffusing ceiling panels, or other creative applications where its 5% light-filtering property is desired.

Critical Fabrication Considerations by Color Group

1. Handling & Contamination Prevention:

Light & White Fabrics (L1-501, L1-502, L1-505, L1-510): These are highly susceptible to showing dirt, oil, or grease. Implement a clean-handling protocol using gloves and ensure work surfaces are meticulously clean before laying out fabric.

Dark Fabrics (L1-506, L1-507, L1-509): While less prone to showing dirt, they can reveal light-colored dust or lint. A dedicated, clean area for handling dark fabrics is recommended to maintain their deep, consistent color.

2. Precision Cutting for Optimal Edges:

Tool Selection: Use razor-sharp, high-quality cutting blades (cold knife or specialized crush cutters) designed for synthetic fabrics. Dull blades will pull and distort the tight weave, creating a frayed or wavy edge that affects both appearance and function.

Pattern Alignment for Two-Tones (L1-502, L1-503, L1-508, L1-510, L1-512): Before cutting full lengths, carefully examine the fabric roll to understand the pattern repeat and alignment. When joining multiple widths or producing multiple units for the same room, cuts must be planned to ensure the pattern matches perfectly at seams and across adjacent windows. This often requires extra yardage and meticulous layout planning.

3. Seaming Methodology for Wide Panels:

To create shades wider than the fabric roll (e.g., >300cm), a strong, flat seam is essential.

High-Frequency (HF) Welding: The recommended method. It creates a fused seam by melting the PVC coatings together under pressure and radio frequency. This results in a joint that is often stronger than the base fabric and, when done correctly, is minimally visible—critical for maintaining the aesthetic of patterned fabrics.

Thermal Tape/Bonding: An alternative method using a heat-activated adhesive tape. It requires precise temperature and pressure control to ensure a permanent, bubble-free bond without discoloring the fabric face.

4. Hem Construction & Bottom Bar Integration:

The bottom hem must be robust and straight to ensure proper hanging and operation.

Sewn Hems: If sewing, use a high-quality, UV-stable polyester thread in a color that matches or complements the fabric. The stitch type (e.g., double-stitch) should provide security against the weight of the bottom bar. Back-tacking at the ends is crucial.

Fabricated Channel/Pocket: Creating a clean pocket for the bottom bar via welding or bonding can provide a streamlined, stitch-free look. Ensure the pocket is perfectly straight and the bar is fully inserted to prevent sagging or twisting.

5. Final Quality Checks:

Roll Test: Before final assembly, manually roll and unroll the fabric on the intended tube to check for consistent tension and the absence of tracking issues or side curl.

Visual Inspection: Under good light, inspect for any manufacturing flaws, alignment errors in patterns, or handling marks, especially on light-colored fabrics.

Adhering to these material-specific protocols ensures that the engineered quality of the L1-500 Sunscreen fabrics is fully preserved and expressed in the finished blind, leading to superior performance and customer satisfaction.