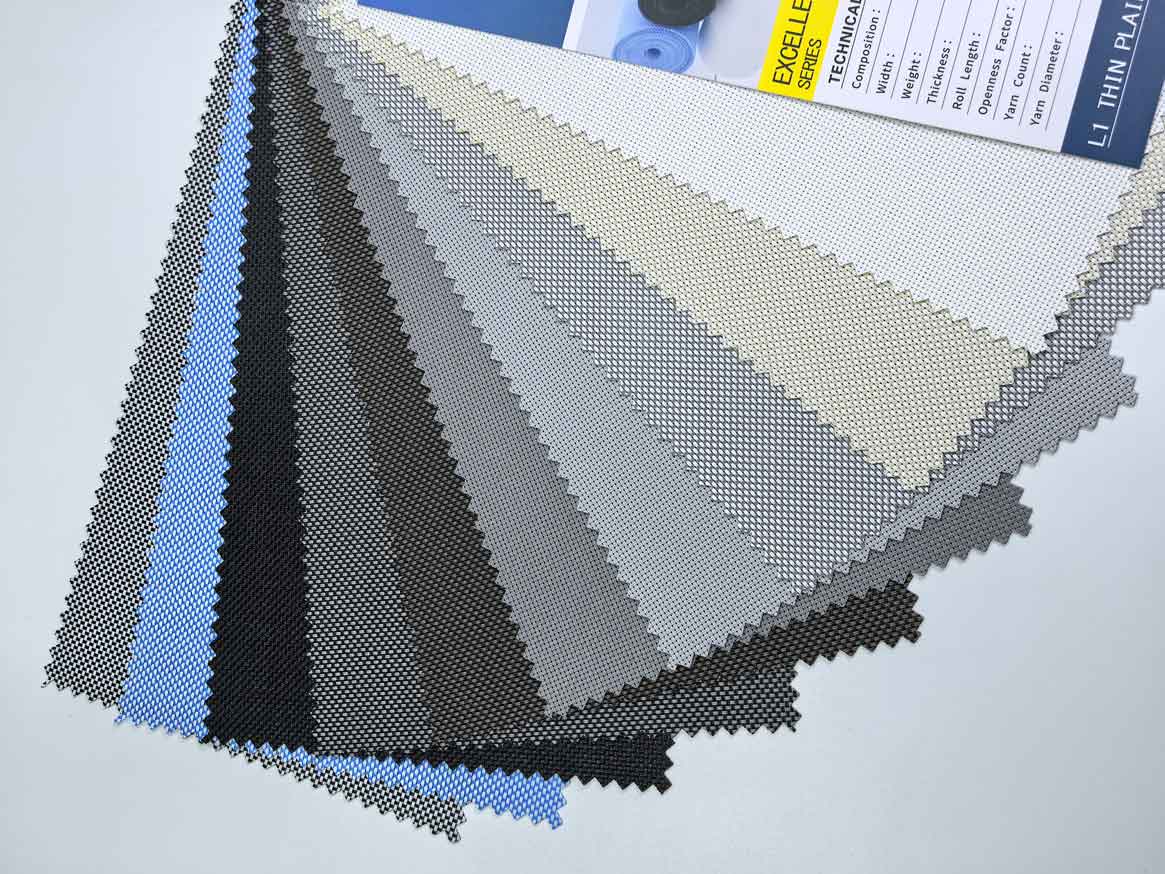

The Material Advantage: Understanding 30% Polyester 70% PVC Window Fabric

At the core of high-performance solar shading products like the L1-500 series lies a specific material science choice: the 30% polyester 70% PVC window fabric composite. This article delves into the engineering rationale behind this prevalent formulation, explaining why this specific balance of materials has become an industry benchmark for durable, effective, and commercially viable Sunscreen fabrics.

The Synergy of Two Materials: Polyester and PVC

The 30/70 ratio is not arbitrary; it represents an optimized balance where each material performs a distinct, complementary role.

The Role of Polyester (30%): The Structural Backbone.

Tensile Strength & Dimensional Stability: The high-tenacity polyester yarns provide the fabric with exceptional strength, resisting tearing and stretching. This ensures the fabric maintains its shape and flat appearance over years of use and under varying tension in roller systems.

Foundation for the Weave: The polyester forms the stable, woven substrate onto which the PVC coating is applied. Its consistent quality is crucial for achieving the precise weave density (e.g., 46x44) that determines optical properties like the openness factor.

The Role of the PVC Coating (70%): The Protective & Functional Shield.

Environmental Resistance: The PVC layer encapsulates the polyester yarns, providing an excellent barrier against moisture, mildew, pollution, and most critically, ultraviolet (UV) radiation. This protection prevents the polyester from degrading and ensures exceptional colorfastness, preventing fading.

Durability & Cleanability: The coated surface is highly resistant to abrasion and is inherently easy to clean—typically requiring only a soft brush, vacuum, or damp cloth. This translates to low maintenance and a long, aesthetically pleasing service life.

Performance Characteristics: The coating process allows for precise control over the fabric's surface properties, including its reflectivity and the stability of its openness factor. It also enables specialized fabrication techniques like high-frequency welding.

Why This Ratio Works for Commercial Applications

The 30% polyester 70% PVC window fabric formulation delivers an ideal balance for both manufacturers and end-users:

Manufacturing Efficiency & Consistency: The materials are readily available and the coating process is highly controlled, allowing for the production of large volumes with consistent color and performance specifications—a key requirement for commercial projects.

Proven Longevity & Cost-Effectiveness: This composite has a decades-long track record in architectural applications. It offers an excellent lifespan (often 10-15 years) relative to its cost, providing strong long-term value. This durability makes it a cornerstone material for commercial-grade Roller blinds Fabrics.

Versatility & Compatibility: Fabrics of this composition are compatible with a wide range of industry-standard fabrication methods (cutting, sewing, welding) and can be integrated into countless blind and shade system designs.

While alternative and emerging materials are explored for niche applications, the 30% polyester 70% PVC window fabric remains the dominant and most trusted solution for broad-market, high-performance solar control. It represents a mature technology where performance, durability, and cost are perfectly balanced, forming the reliable foundation for product families like the LEAPKA L1-500 series.