Technical Portfolio: The L1-505 to L1-512 Fabric Series

For professionals seeking a cohesive yet varied aesthetic within a fixed performance envelope, the latter segment of the L1-500 series—encompassing L1-505 through L1-512—offers a sophisticated palette of mid-tones, deep hues, and graphic patterns. This article provides a structured technical comparison of these five specific Sunscreen fabrics, detailing how their shared engineering foundation supports diverse visual outcomes for project specification.

Product Line Definition & Aesthetic Positioning

This group is defined by its progression from neutral greys to high-contrast designs, all maintaining the series' core 5% openness factor:

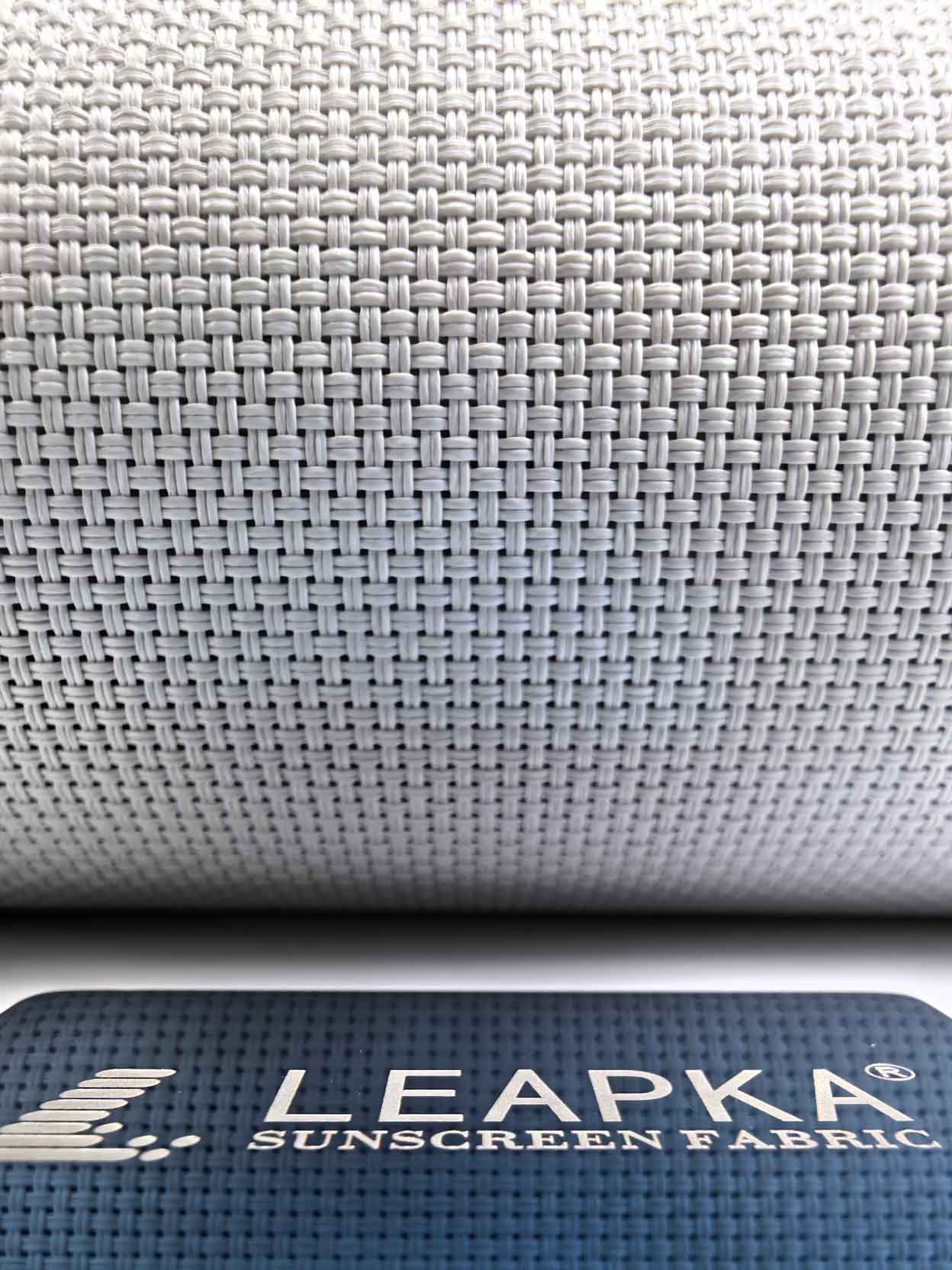

L1-505 (Light Grey): A soft, versatile mid-tone grey. Serves as a contemporary neutral that is less stark than pure white, reducing visual contrast with window frames and exterior views.

L1-506 (Dark Grey): A deep, solid grey. Offers a stronger architectural statement and provides increased light absorption for enhanced glare control in specific settings, while maintaining the 5% view-through.

L1-509 (Black): A pure, solid black fabric. Delivers maximum contrast against bright exteriors and offers the highest level of light absorption within the 5% openness parameter, ideal for creating focused, intimate environments.

L1-510 (White/Blue): A two-tone fabric with a crisp, graphic quality. The white and blue yarns create a refreshing, patterned appearance suited for thematic or vibrant interior schemes.

L1-512 (Black/White): A high-contrast, classic two-tone fabric. Creates a dynamic, textural visual effect that is both modern and timeless, effectively disguising minor surface imperfections due to its busy pattern.

Unified Performance Foundation

All five products are manufactured to identical technical standards, ensuring predictable solar and thermal performance irrespective of color selection.

Parameter Specification (Uniform across L1-505 to L1-512) Functional Implication

Composition 30% Polyester / 70% PVC Coating Ensures durability, dimensional stability, and resistance to UV degradation, moisture, and staining.

Weight 420 g/m² (±5%) Provides optimal substance for smooth operation in roller systems, offering stability without excessive bulk.

Thickness 0.60 mm (±5%) Allows for a compact roll in cassette systems and consistent handling during fabrication.

Openness Factor 5% (±0.5%) The defining constant. Effectively diffuses direct sunlight to eliminate glare while preserving outward visibility and admitting soft natural light.

Weave & Construction Plain Weave, 46 x 44 thread count, 0.32mm yarn diameter Creates a uniform, fine surface that ensures consistent optical performance and a high-quality finish.

Standard Formats Widths: 200cm, 250cm, 300cm. Roll Length: 35m. Accommodates a wide range of window sizes and facilitates efficient project logistics.

Comparative Selection Guide

Choosing between these variants is primarily an aesthetic and psychological decision informed by the project's goals:

For a Subtle, Receding Backdrop: Choose L1-505 Light Grey.

For a Bold, Architectural Statement with Depth: Choose L1-506 Dark Grey or L1-509 Black.

For a Thematic or Vibrant Accent: Choose L1-510 White/Blue.

For a Dynamic, Patterned Effect that Hides Imperfections: Choose L1-512 Black/White.

This segment of the L1-500 series demonstrates that within a rigid framework of performance engineering—making them reliable Roller blinds Fabrics—there exists significant freedom for design expression through color and pattern, allowing these Sunscreen fabrics to meet both precise functional requirements and specific aesthetic visions.