The Strategic Logic of Specifying Custom Width Sunscreen Fabric Rolls

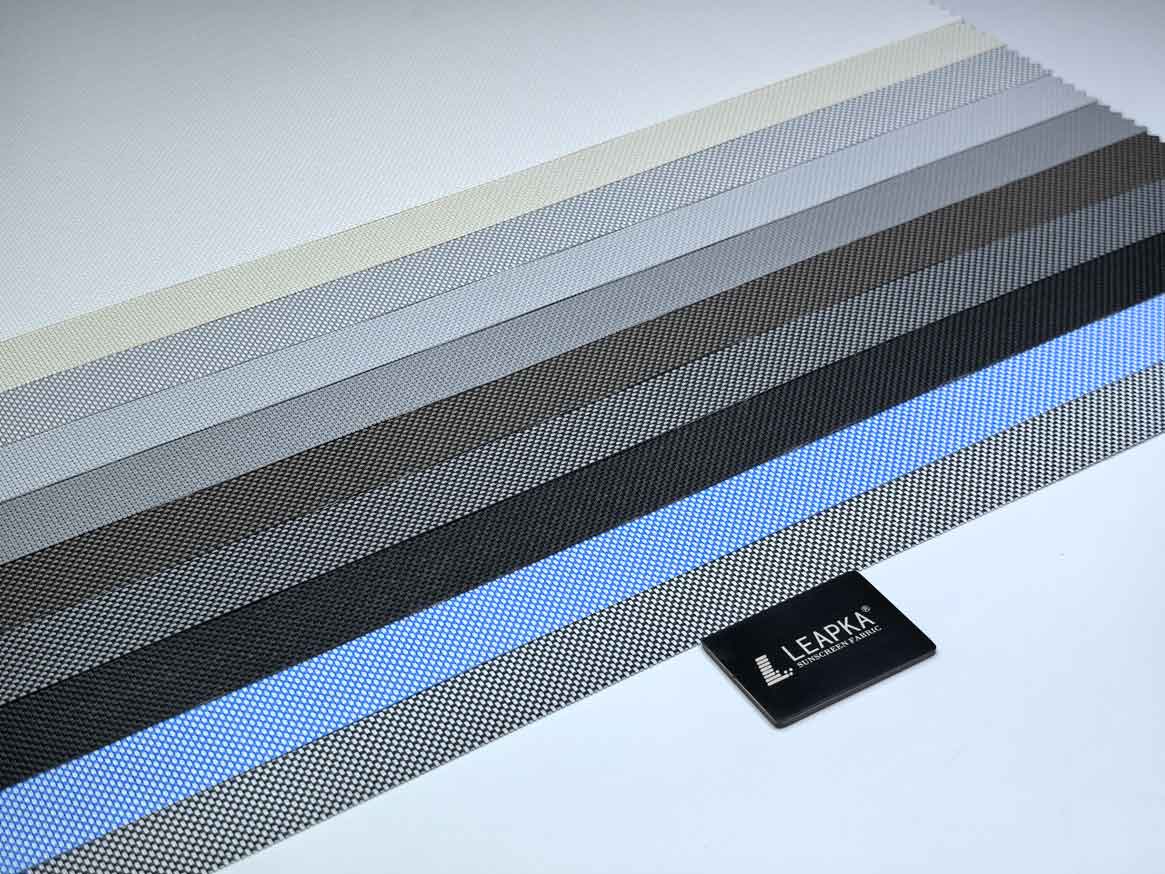

In the domains of commercial construction, large-scale residential development, and specialist fabrication, the decision to source custom width sunscreen fabric rolls is a mark of professional foresight and operational intelligence. Procuring materials like the L1-500 series in exact, project-specific dimensions delivers concrete advantages in cost management, aesthetic quality, and installation efficiency.

Driving Economic Efficiency Through Precision

Standard-width material inevitably leads to waste. When window or glazing unit widths are 270cm, 340cm, or any dimension not matching the 200/250/300cm standard, significant portions of the roll become off-cuts. These represent direct financial loss in material cost and contribute to project waste streams. Custom width sunscreen fabric rolls are manufactured to the precise millimeter specified in the project’s fenestration schedule. This precision can reduce fabric waste by 15-30% on a typical project, directly improving the bottom line. It transforms material estimation from an exercise in approximation to an exact calculation, eliminating budget contingencies for trimming loss and supporting more sustainable construction practices by minimizing landfill contributions.

Guaranteeing Unblemished Aesthetic Outcomes

The Seamless Visual Field: For monumental glazing, curtain walls, or any application where visual continuity is paramount, the ability to cover the span with a single, unjoined piece of fabric is invaluable. It eliminates vertical seams, which—even when expertly executed—can catch light differently or disrupt the pattern flow, especially on graphically striking fabrics like the L1-512 Black/White. The result is a pristine, monolithic appearance that fully realizes the architect’s design intent.

Factory-Edge Quality Assurance: Field-cutting, even with skilled personnel, carries inherent risks: imperfectly straight cuts, potential edge-fraying, or contamination from workshop environments. Custom width sunscreen fabric rolls are precision-cut in a controlled manufacturing setting. The customer receives a product with factory-perfect edges, and the integrity of the fabric’s coating and color is assured right up to the cut line, as it was produced to that final dimension.

Optimizing the Supply Chain and Installation Process

This approach fundamentally redefines the fabric’s role on-site. It shifts from a raw material requiring skilled transformation to a pre-engineered component ready for installation. This has profound implications:

Simplified Logistics: Procurement becomes cleaner—ordering exact sizes per opening simplifies tracking and inventory.

Reduced On-Site Labor & Risk: Installers are effectively assembling a kit rather than fabricating from scratch. This drastically cuts on-site labor time, minimizes the potential for costly measurement or cutting errors, and reduces the need for specialized cutting tools on-site.

Faster Project Turnaround: With pre-sized components, the installation phase is accelerated, allowing for quicker project completion and client handover.

For the specifying professional, opting for custom widths is a powerful demonstration of meticulous project management. It ensures the final installed product is a direct, unadulterated reflection of the design, marrying the high performance of Sunscreen fabrics with flawless execution.