Fabrication Protocol: Best Practices for L1-500 Series Products

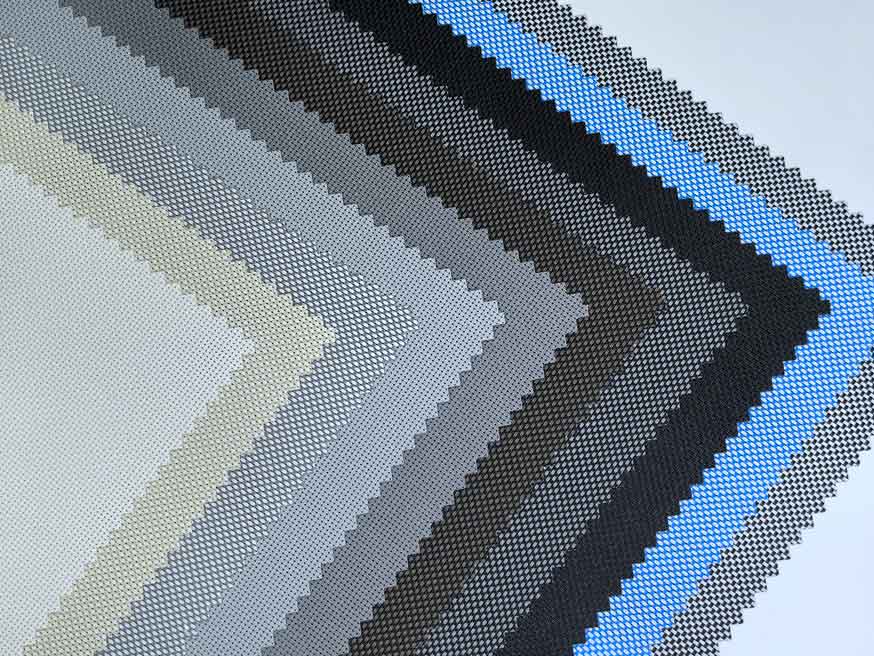

Transforming the L1-500 series from its roll form into premium, operational window coverings is a process demanding precision and an understanding of its material-specific properties. This guide details the viable end-products and outlines critical manufacturing considerations—with special attention to color-based handling—for fabricators working with this line of Roller blinds Fabrics.

Viable End-Product Configurations

The series' properties make it ideally suited for several mainstream applications:

Interior Roller Shades/Blinds: The primary and most common use. Its 420 g/m² weight and 0.60mm profile ensure smooth operation in both simple roller tubes and integrated cassette systems for a streamlined appearance.

Vertical Blind Alternatives: The fabric can be precisely slit into vertical panels for use in specialized track systems, offering a unified, soft appearance for sliding doors or room dividers, as opposed to traditional rotating louvres.

Custom Architectural Features: For bespoke projects, it can be employed in fixed or operable interior screens, ceiling baffles, or other design elements where its light-filtering quality is a desired feature.

Critical Manufacturing Considerations

1. Pre-Production: Handling and Layout

Color-Sensitive Protocols:

*Light/White Fabrics (L1-501, L1-502, L1-505, L1-510):* These are highly susceptible to visible soiling. Implement a clean-room-style protocol: use lint-free gloves, ensure work surfaces are impeccably clean, and dedicate specific areas for handling these variants to avoid cross-contamination from darker fabrics.

*Dark Fabrics (L1-506, L1-507, L1-508, L1-509, L1-512):* While less prone to showing dirt, they attract and reveal light-colored dust and lint. A separate, dedicated clean space for their handling is equally important to maintain their deep, uniform color.

Pattern Management for Two-Tones: For fabrics like L1-512 (Black/White) or L1-510 (White/Blue), careful examination of the roll is essential before cutting. Document the pattern repeat. When sewing multiple widths together for an extra-wide shade or producing multiple units for a single room, precise cutting and layout are required to ensure the pattern aligns seamlessly across seams and from one window to the next. This often necessitates ordering additional yardage for pattern matching.

2. Cutting: Achieving Precision Edges

Tooling: Employ sharp, high-quality cutting systems—whether cold knife or calibrated crush cutters. Dull blades will tug and distort the tight plain weave, creating a frayed or wavy edge that compromises both the visual finish and the fabric's ability to track straightly in side channels.

Technique: Ensure cuts are perfectly square to the selvage. A skewed cut will result in a blind that hangs diagonally or rolls unevenly.

3. Seaming: Creating Wide-Width Panels

For panels exceeding standard roll widths, a strong, flat, and visually minimal seam is critical.

High-Frequency (HF) Welding: The preferred industrial method. It fuses the PVC coatings of two fabric edges under pressure and radio frequency, creating a bond that is often stronger than the base material. When executed correctly, it results in a very flat, discreet seam, essential for maintaining the aesthetic of patterned fabrics.

Thermal Bonding with Tape: An alternative using a heat-activated adhesive tape. This requires exact control of temperature, pressure, and dwell time to achieve a permanent, bubble-free bond without causing thermal discoloration or "ghosting" on the fabric face.

4. Hem and Bottom Bar Attachment

The hem must be robust to support the bottom bar’s weight and ensure a straight, stable lower edge.

Sewn Hem Construction: If sewing, select a high-tenacity, UV-stable polyester thread in a color that blends with the fabric. Use a reinforced stitch pattern (e.g., a double stitch) and ensure secure back-tacking at both ends to prevent unraveling under tension.

Fabricated Pocket Hem: Creating a clean pocket via welding or bonding eliminates stitching. It is imperative that this pocket is formed perfectly straight and that the bottom bar is fully inserted to prevent twisting or an uneven hang.

5. Final Verification

Functional Roll Test: Prior to final assembly, manually wind and unwind the fabric on the roller tube to check for consistent tension and the absence of tracking issues (sideways movement) or curling edges.

Comprehensive Visual Inspection: Under bright, even lighting, scrutinize the entire panel for any fabrication flaws, alignment errors in patterns, or inadvertent marks, paying particular attention to light-colored fabrics.

Adherence to these disciplined protocols ensures the intrinsic quality engineered into the L1-500 Sunscreen fabrics is faithfully translated into the final product, yielding Roller blinds Fabrics of exceptional performance and finish.