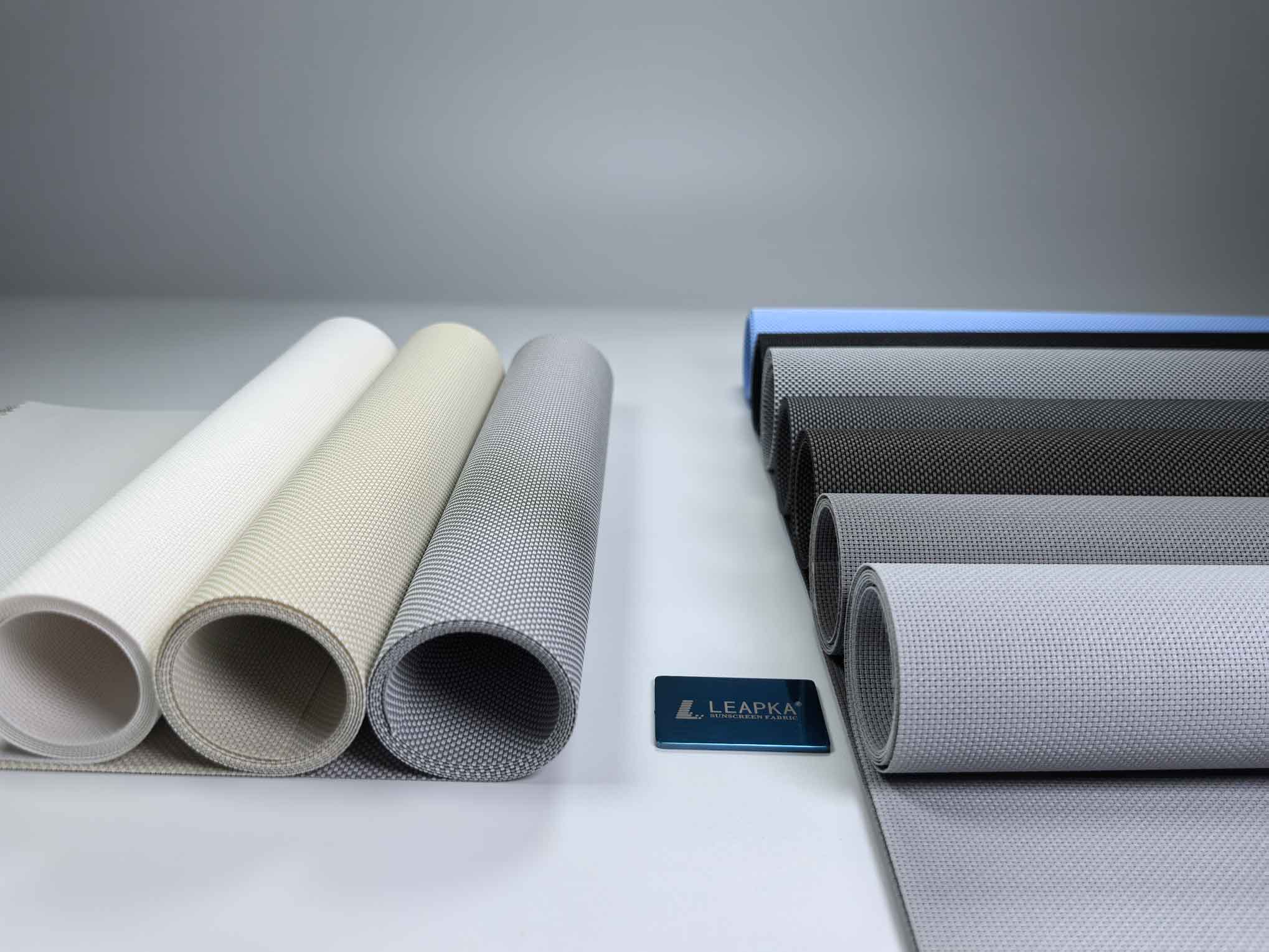

Fabrication Guidelines for L1-500 Series Window Coverings

Transforming rolls of L1-500 series fabric into high-performing, aesthetically flawless window treatments requires an understanding of its material properties and the application of precise fabrication techniques. This guide outlines the end-product possibilities and critical manufacturing considerations for working with this versatile Sunscreen fabric.

Primary End-Product Applications

The L1-500 series is ideally suited for several popular shading solutions:

Internal Roller Blinds/Shades: The most common application. The fabric's 420 g/m² weight and 0.60mm thickness ensure smooth rolling and a clean, flat appearance when extended. It works well in both standard roller systems and sleek cassette housings.

Motorized Roller Shades: The fabric's consistent weight and flexibility make it perfectly compatible with a wide range of tubular motors from brands like Somfy, Lutron, and others, enabling integration into smart home and building automation systems.

Vertical Blinds (Louver Replacements): While less traditional, the fabric can be cut into vertical strips for use in certain track systems, offering a unique aesthetic and the same 5% light-diffusing properties for sliding doors or room dividers.

Critical Fabrication Considerations

1. Pattern Matching and Alignment:

For the two-tone fabrics (L1-502, L1-503, L1-508, L1-510, L1-512), meticulous attention must be paid to pattern alignment. When creating a blind wider than the fabric roll (requiring a seam) or when producing multiple blinds for the same space, the pattern must be matched perfectly across seams and from one blind to the next. This requires careful planning during the cutting layout phase.

2. Precision Cutting for Clean Edges:

Cold Knife/Roller Cutting: Using a sharp, precision blade is essential to achieve a clean, straight cut without pulling or fraying the yarns. A ragged edge will be visible on the side of the blind and can affect smooth operation.

Crush Cutting: This method can provide a sealed edge. Tool maintenance is critical to ensure a clean, consistent cut along the entire length.

3. Seaming for Width: Creating Invisible Joins

To create blinds wider than the standard fabric width (e.g., 300cm+), seaming is required. The goal is a strong, flat, and nearly invisible seam.

High-Frequency (HF) Welding: This is the recommended method for the L1-500 series. It uses radio waves to melt the PVC coating layers together under pressure, creating a joint that is often stronger than the base fabric and has minimal visual impact, crucial for maintaining the aesthetic of patterned fabrics.

Thermal Seaming (Heat Welding): An alternative method that uses a heated element to bond the fabric edges. It requires precise temperature control to melt the PVC coating without damaging the polyester yarns.

4. Hem and Bottom Bar Attachment:

The bottom hem must securely hold the weight bar and present a clean finish.

Sewn Hems: If sewing is used, a UV-resistant polyester thread must be selected to prevent degradation from sun exposure. The stitch type and density should be chosen to distribute stress and prevent tearing.

Welded/Pocket Hems: Creating a pocket for the weight bar using HF or thermal welding can provide a very clean, stitch-free finish. Ensuring the pocket is straight and the bar is fully inserted is key to a flat, hang-free bottom edge.

5. General Handling and Cleanliness:

Light Colors (L1-501, L1-502, L1-505, L1-510): These fabrics can show marks from dirty hands or work surfaces. Clean gloves and a dedicated, clean cutting/pasting table are advisable.

Rolling Tension: When assembling the blind, the fabric must be wound onto the roller tube with even, appropriate tension. Incorrect tension can lead to uneven rolling, side curl, or operational issues.

By respecting these material-specific guidelines, manufacturers can ensure that the inherent quality and aesthetic appeal of the L1-500 series Roller blinds Fabrics are fully realized in the final product, leading to satisfied end-customers and successful project installations.