The Strategic Advantages of Custom Width Sunscreen Fabric Rolls

For large-scale projects, retrofit applications, or designs with non-standard fenestration, the ability to order custom width sunscreen fabric rolls transitions from a convenience to a critical project advantage. Specifying the exact width required delivers tangible benefits in cost, aesthetics, and installation efficiency, particularly when working with comprehensive series like the L1-500.

Optimizing Material Yield and Minimizing Waste

Standard width rolls (200cm, 250cm, 300cm) often necessitate trimming, leading to significant off-cuts, especially when window widths don't align perfectly with these metrics. Custom width sunscreen fabric rolls are manufactured to the project's precise specifications. This precision dramatically reduces material waste—by 15% or more on large projects—directly lowering material costs and aligning with sustainable construction practices by minimizing landfill debris.

Enhancing Aesthetic Integrity and Simplifying Installation

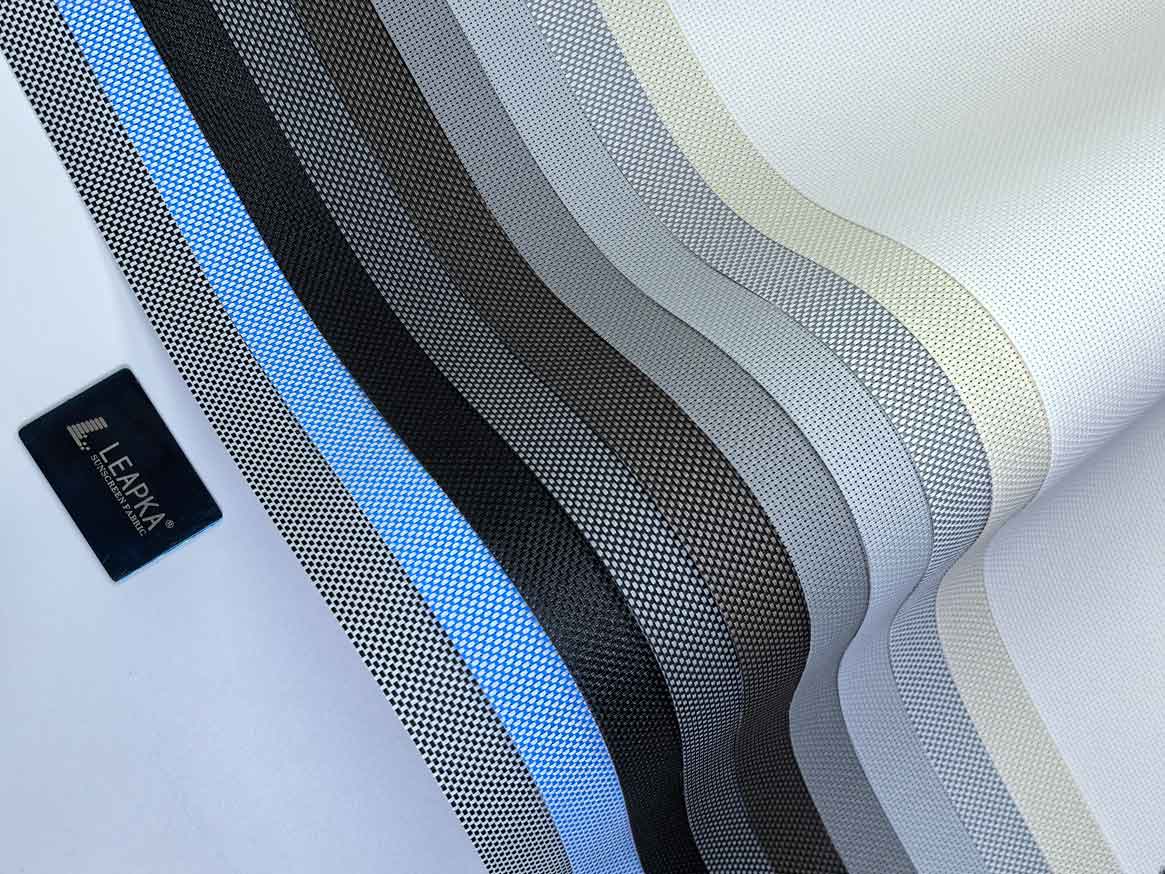

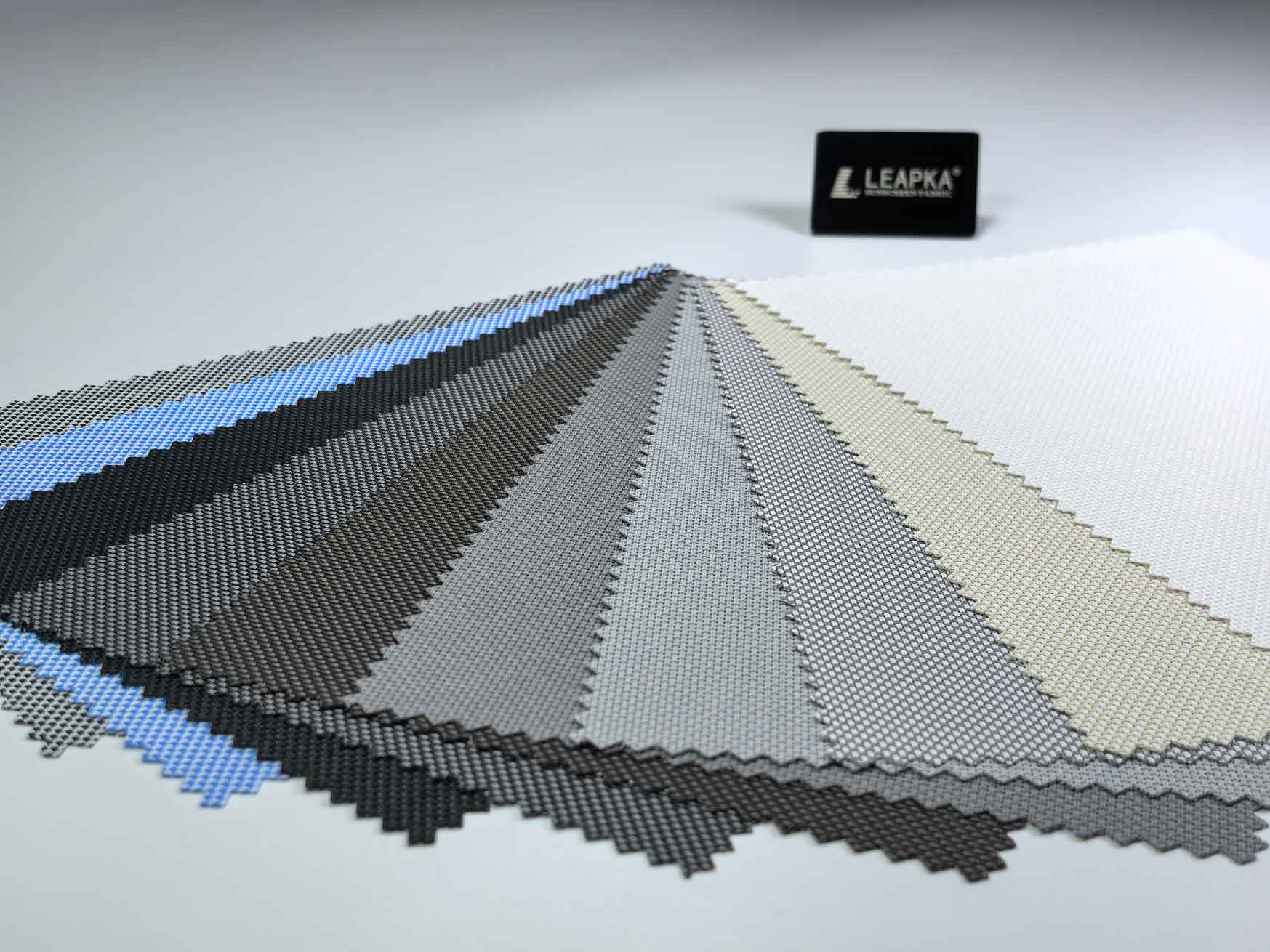

Seamless Appearance: For extra-wide windows, using a single, custom-width piece of fabric eliminates the need for a vertical seam. This results in a flawless, uninterrupted visual field, which is especially important for the two-tone patterns in the L1-500 series, where pattern matching across a seam, while possible, is avoided altogether for a perfect finish.

Streamlined Installation: Installers receive fabric that is already cut to the exact width. This eliminates time-consuming and error-prone measuring and cutting on-site, reduces the number of tools required, and accelerates the installation process. It also removes the risk of costly cutting mistakes during field fabrication.

Technical Consistency and Project Management

Ordering custom width sunscreen fabric rolls from the manufacturer ensures that the fabric's critical performance properties—the 5% openness factor, the coating integrity, and the color consistency—are maintained across the entire custom roll. This is guaranteed through controlled factory processes, unlike field-cutting which can potentially compromise edge seals. Furthermore, it simplifies logistics and procurement; the project manager orders a single, precise item per window specification, streamlining inventory and ensuring all materials arrive ready for installation.

For architects and contractors, specifying custom widths is a mark of detailed project planning. It demonstrates a commitment to precision, waste reduction, and flawless final execution, ensuring that the high quality of the Sunscreen fabrics is matched by the quality of the installed application.